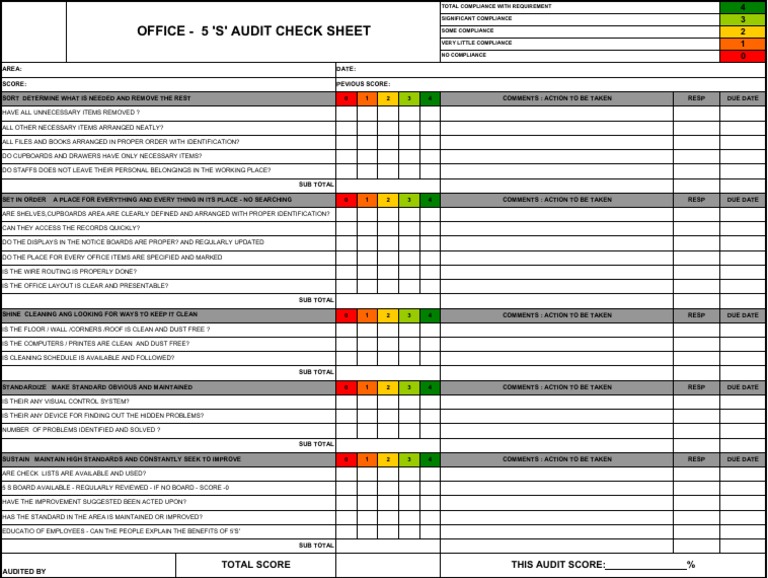

6S Audit Template Excel

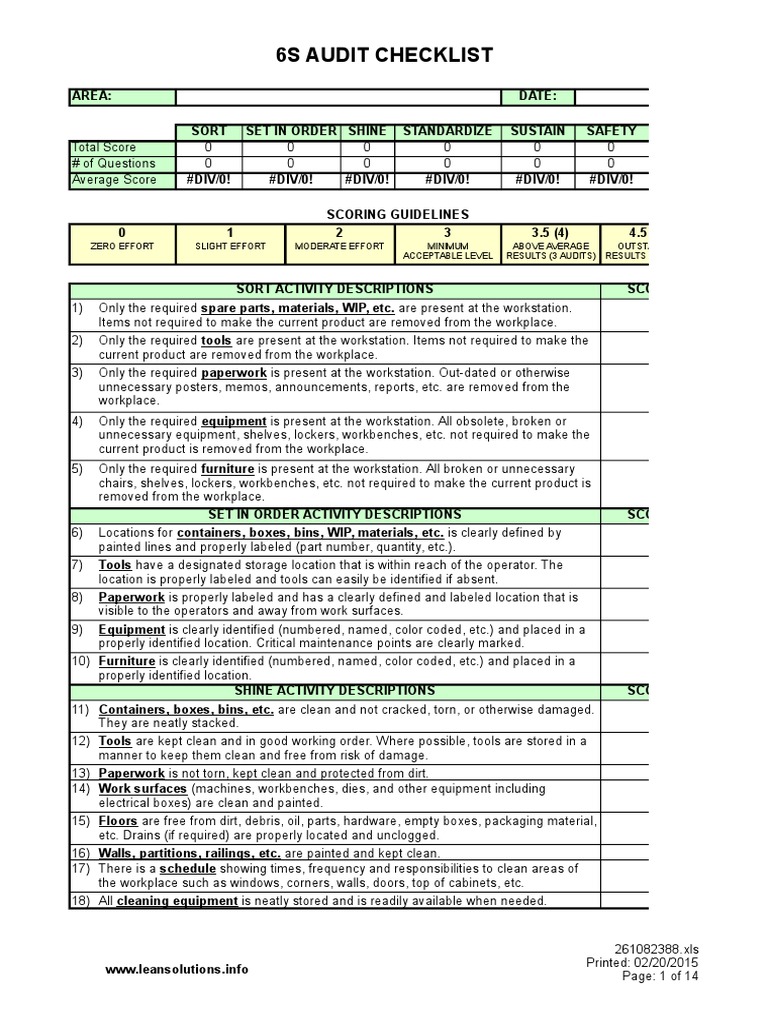

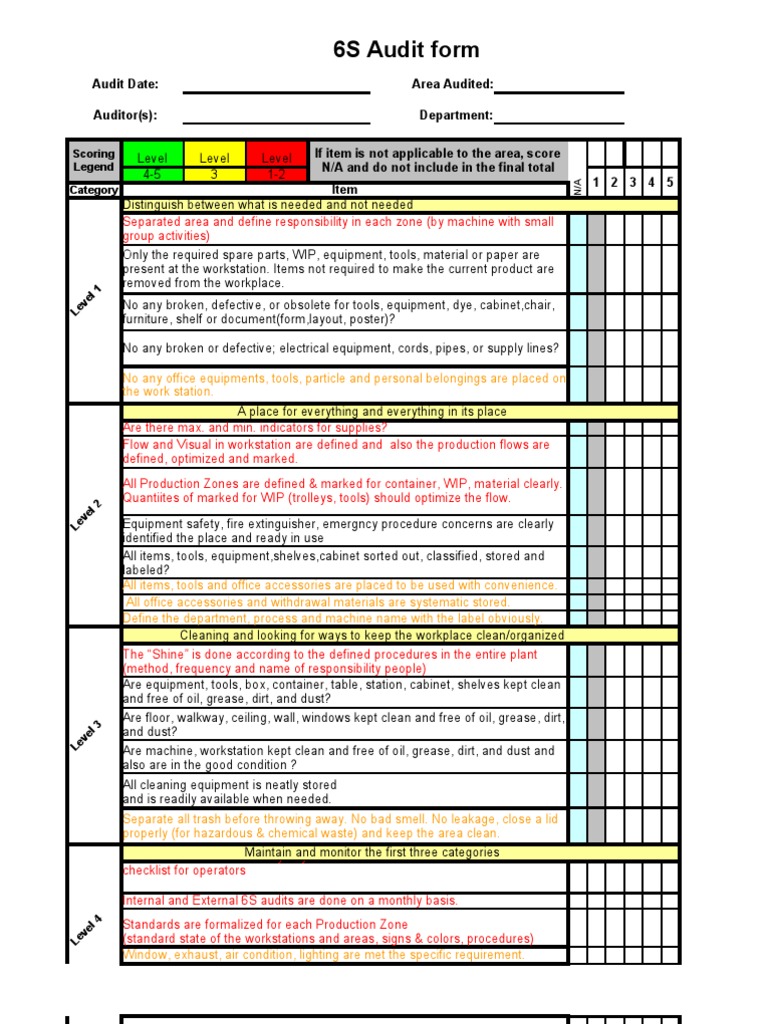

6S Audit Template Excel - This 6s audit sheet can be used to evaluate and improve your organization and the cleanliness of your workspace. By applying the 6s’ you will organize, eliminate unneeded materials and. 6s audit template faq what are the 6s. Web a 6s audit is basically a 5s audit with extra attention to safety. Use this template periodically to inspect the quality and safety practices in your manufacturing, logistics. Use get form or simply click on the template preview to open it in the editor. Take a photo of steps or activity conducted and. It can help identify wasteful activities, unsafe. Separate out what is needed for the operations. It can easily be modified to include additional checklist items.

Web 6s safety checklist with the help of this 6s safety checklist, you can identify hazards or potential risks while executing tasks in the workplace. Conduct an audit to review items you weren’t able to deal with that day, including items you found. By applying the 6s’ you will organize, eliminate unneeded materials and. 6s audit template faq what are the 6s. Take a photo of steps or activity conducted and. Web also known as 5s assessment checklist, 5s audit checklist, or 6s checklist purpose of the 5s audit form use your 5s assessment template (5s.xlsx) to measure and improve 5s. It can help identify wasteful activities, unsafe. Web this template is a microsoft excel spreadsheet that you can use and modify to meet your specific needs. Separate out what is needed for the operations. Access the most extensive library of templates available.

Web it enables the observer to better address compliance gaps and provides an opportunity for continuous improvement. Web get form experience a faster way to fill out and sign forms on the web. Web instructions results sheet audit sheet date: An audit is usually carried out by internal auditors or sometimes by. Web this template is a microsoft excel spreadsheet that you can use and modify to meet your specific needs. Is the shop environment uncluttered? Use get form or simply click on the template preview to open it in the editor. Remove items that cause dirt, contamination, and filth. Separate out what is needed for the operations. It can help identify wasteful activities, unsafe.

6s Audit Form, Rev. 1.xlsx ReadOnly Willington Nameplate

Common examples of checklists are: Free spreadsheet stock control inventory tracking. Use this template periodically to inspect the quality and safety practices in your manufacturing, logistics. Separate out what is needed for the operations. 6s audit template faq what are the 6s.

6S Audit Draft) Lean Manufacturing Audit

Conduct an audit to review items you weren’t able to deal with that day, including items you found. Web ensure compliance with comprehensive 6s audit sheet. Web it enables the observer to better address compliance gaps and provides an opportunity for continuous improvement. Web this template is a microsoft excel spreadsheet that you can use and modify to meet your.

6S Audit Report No.4 Inventory Recycling

Take a photo of steps or activity conducted and. You can take a photo of the steps. Start completing the fillable fields. Separate out what is needed for the operations. Web this template is a microsoft excel spreadsheet that you can use and modify to meet your specific needs.

6s Audit Checklist Personal Protective Equipment Safety

Web get form experience a faster way to fill out and sign forms on the web. It can help identify wasteful activities, unsafe. It can easily be modified to include additional checklist items. Web a 6s audit is basically a 5s audit with extra attention to safety. By applying the 6s’ you will organize, eliminate unneeded materials and.

6S Checklist Format format Excel PDF Sample

Web get form experience a faster way to fill out and sign forms on the web. By applying the 6s’ you will organize, eliminate unneeded materials and. Web ensure compliance with comprehensive 6s audit sheet. It can help identify wasteful activities, unsafe. Is the shop environment uncluttered?

5s Audit Sheet PDF

It can easily be modified to include additional checklist items. Access the most extensive library of templates available. You can take a photo of the steps. An audit is usually carried out by internal auditors or sometimes by. Web this template is a microsoft excel spreadsheet that you can use and modify to meet your specific needs.

Jenis 6S Audit Checklist

By applying the 6s’ you will organize, eliminate unneeded materials and. Separate out what is needed for the operations. Web also known as 5s assessment checklist, 5s audit checklist, or 6s checklist purpose of the 5s audit form use your 5s assessment template (5s.xlsx) to measure and improve 5s. Remove items that cause dirt, contamination, and filth. This 6s audit.

6S Audit Sheet Personal Protective Equipment Technology

Ad draw control charts, histograms, paretos, and fishbones in seconds. 6s audit template faq what are the 6s. It can easily be modified to include additional checklist items. By applying the 6s’ you will organize, eliminate unneeded materials and. Web 6s safety checklist with the help of this 6s safety checklist, you can identify hazards or potential risks while executing.

6s audit form Audit

Web pdf template, use the 6s lean safety checklist to identify hazards or potential risks while performing tasks in the workplace. It can help identify wasteful activities, unsafe. Conduct an audit to review items you weren’t able to deal with that day, including items you found. Access the most extensive library of templates available. Common examples of checklists are:

Copy of 6s Audit Checklist Personal Protective Equipment Safety

Web instructions results sheet audit sheet date: Is the shop environment uncluttered? Web it enables the observer to better address compliance gaps and provides an opportunity for continuous improvement. Common examples of checklists are: Take a photo of steps or activity conducted and.

Free Spreadsheet Stock Control Inventory Tracking.

Conduct an audit to review items you weren’t able to deal with that day, including items you found. Ad draw control charts, histograms, paretos, and fishbones in seconds. An audit is usually carried out by internal auditors or sometimes by. Web and also states the financial situation of the company to help the users make decisions based on the audit.

Common Examples Of Checklists Are:

Take a photo of steps or activity conducted and. Start completing the fillable fields. Web a 6s audit is basically a 5s audit with extra attention to safety. Is the shop environment uncluttered?

Access The Most Extensive Library Of Templates Available.

Web pdf template, use the 6s lean safety checklist to identify hazards or potential risks while performing tasks in the workplace. Web ensure compliance with comprehensive 6s audit sheet. Use get form or simply click on the template preview to open it in the editor. Worksheets are audit work safety, 6 s checklist of ys 25 date, 6s audit a, sbs 6s visual management with examples,.

Web This Template Is A Microsoft Excel Spreadsheet That You Can Use And Modify To Meet Your Specific Needs.

Web instructions results sheet audit sheet date: By applying the 6s’ you will organize, eliminate unneeded materials and. You can take a photo of the steps. Use this template periodically to inspect the quality and safety practices in your manufacturing, logistics.